Please Click Here to View the Video

Downspout Pipe Roll Forming Machine

1. Main Features

In order to provide a complete drainage system-and complete all the work "inside"-

You need a sinker to complement your seamless skypipe.

The downspout machine has the following characteristics:

1) Make downspouts and elbows (for engineering convenience, carry them with you)

2) There are downspouts and round downspouts for maintenance

3) Simple operation and low maintenance cost

4) Stable and efficient

2. Detailed Image of Downpipe Pipe Rolling Mill

Machinery Order

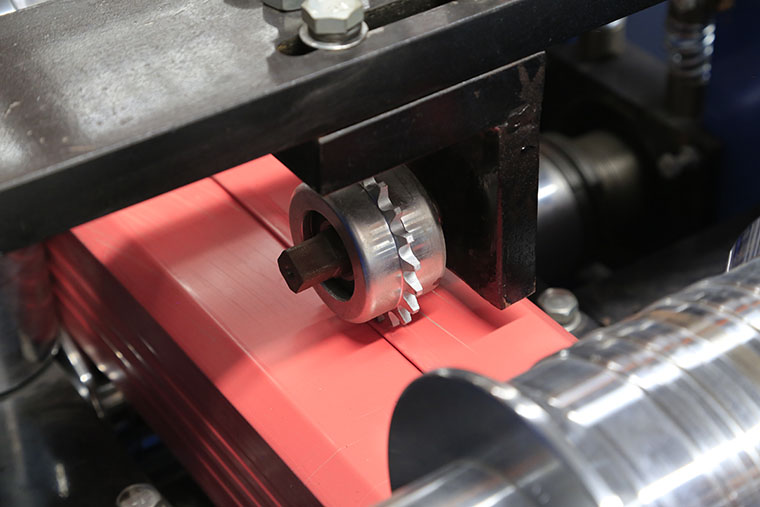

1) D's own tooth spraying device of tube roll forming machine

Brand: BMS Original: China

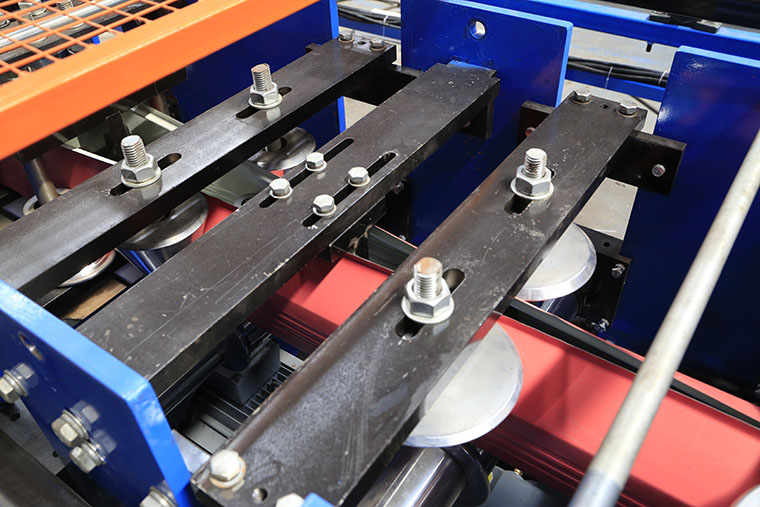

2) Downspout Roll Forming Machine Roller

The roller is made of high-quality steel 45#, CNC lathes,Hard chrome platingtreatment,

style adopts #450 H-shaped steel welding

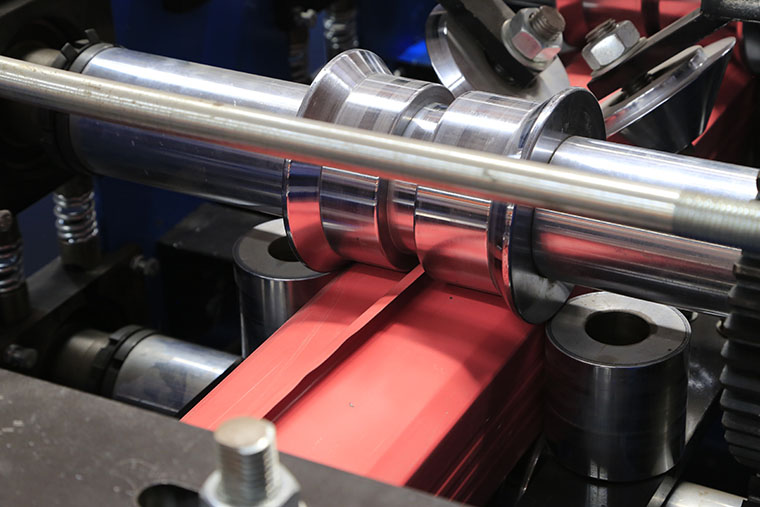

3) Rear Cutter of Downspout Roll Forming Machine

Made of high-quality Cr12 through mold heat treatment

Tool post adopts 20mm high quality steel plate welded hydraulic hydraulic motor: 4KW, hydraulic range: 0-16Mpa

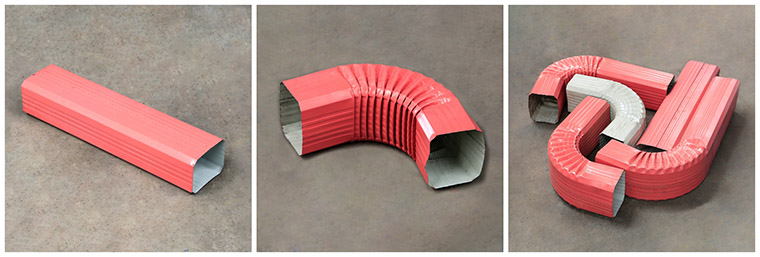

4) Bending Device of Downspout Pipe Bender

5) Downspout Roll Forming Machine Product Display

6) PLC Control System of Downspout Roll Forming Machine

PLC control system (touch screen brand: German Schneider Electric/Taiwan WEINVIEW,

Imported brand: Finland VOCAN/Taiwan DELTA/ALPHA, encoder brand: Japan Koyo/Omron)

7) Downspout Roll Forming Machine Uncoiler

Un-power, manual control of steel coil inner hole shrinkage and stop

Maximum. Feeding width: 500mm, coil inner diameter range 508mm±30mm

Capacity: up to 3 tons

6) Exit Rack

Un- power, one set

Other Details

Suitable for materials with a thickness of 0.4-0.6mm

The shaft is made of 45#, pigment processing = φ75mm, precision

Motor drive, gear chain drive, 14 rollers forming

After Sale Servicve

1、The warranty is 24 months after the client receives the machine. Within the 24 months, we will courier the

replacement parts to the client free of charge.

2、We offer technical support for the entire life of our machines.

3、We can sent our technicians to install and train the workers in the clients' factories with extra cost.

Packing Method

Main body of machine is naked and covered by plastic film ( to protect of dust and corrosion), loaded into container

and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.