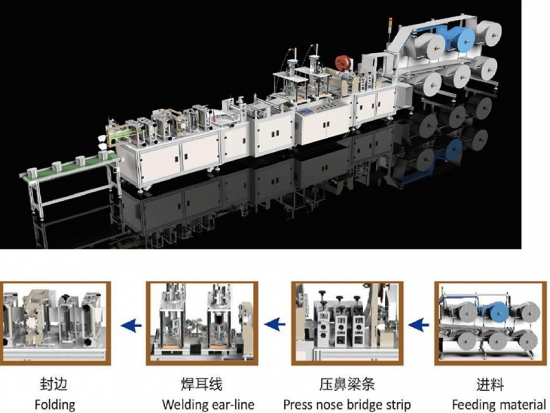

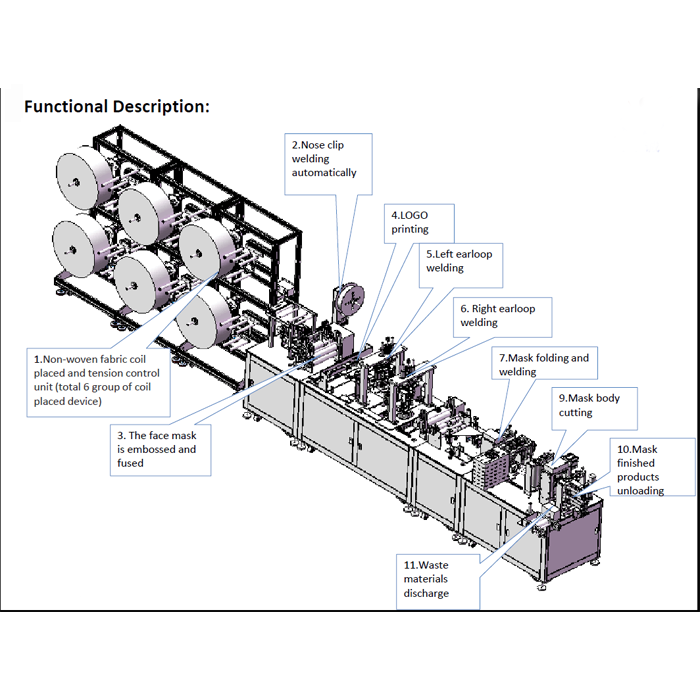

Machine Features:

The new design of the whole machine, the full computer double frequency converter control,parameter setting, simple operation, auto error stop and display, fault display at a glance,positioning and automatic stopping function, simple transmission system, in line with the safety standards of class II medical devices.The thickness of the mask and the length of the nose bridge strip can be adjusted within a certain range. Both-sides ear-loop can be delivered and cut automatically, welded firmly, folded, formed,and waste will be removed. Adjustable producing speed according to different materials,production quality very stable,and high production efficiency.Advantage: Product positioning with high accuracy, low noise, smooth movement and stable performance.Remote operation control function is optional WITH EXTRA COST USD2980, including installation & training.

Main Parameters:

|

Model |

BMS-N95 |

|

|

Production Size |

150mm*105mm |

|

|

Air Supply |

0.8M pa |

|

|

Speed |

40-50pcs/min |

|

|

Power / Voltage |

12KW / AC220V |

|

|

Net Weight |

2600kg |

|

|

Machine Dimension |

11200*1400*2200mm |

|

Producing time: about 10 workdays after received the payment Period of Validity for Price: 30 days from quotation date

Packing method: with nude packing steadily fixed in container suitable for long-distance transportation.

OTHER TERMS:

1. Electric standard: 380V or 415V or 440V/50Hz or 60Hz /3Ph--should be confirmed

2. Major Color of Machine Painting: Blue(RAL5015)+Orange(RAL2004)-factory standard or customized

3. TERMS OF PAYMENT: 100% Deposit is required within five (5)-business days from the contract signing date

4.TESTING MATERIAL: It is the responsibility of the buyer to supply sufficient testing material at least 25 days prior to shipment; all costs relating to the local transport, customs clearance and local taxes for the sample material will be paid by the customer.

5.After sale service:

1)In correct operation & maintaining, the machine is guaranteed for 12months from the date of the successful installation and commissioning of the equipments at the Buyer’s Installation site.(the spare parts stock are available for IMMDEIATELY SERVICE);

2) If necessary, we will dispatch a technician to the factory abroad to install & regulate the machine with USD100/day. The buyer should assist our technician to get the visa and should pay for the air around ticket and the local accommodation.