Work Flow of Howick,FrameCAD style Floor Joist Forming Machine:

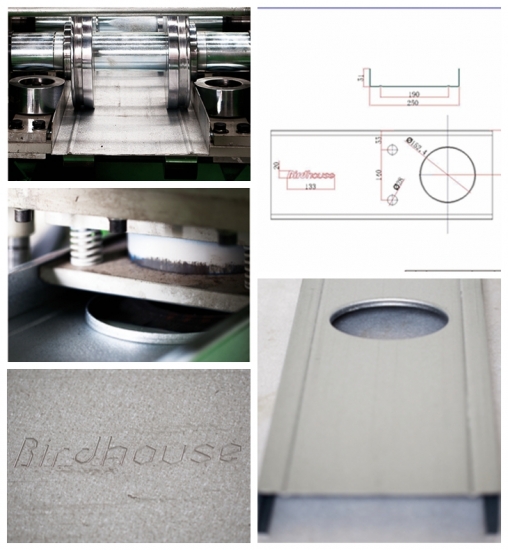

3Tons Decoiler →Roll Forming Mill(7.5kw)→ Hydraulic Cutting Device(post cutting,5.5kw)→PLC Control System→Product Rack(including 3 sets of punching mould: one for 6" dimpled round hole for HVAC, plumbing and electrical,one for 2.8" round hole,and another for customized LOGO embossing)

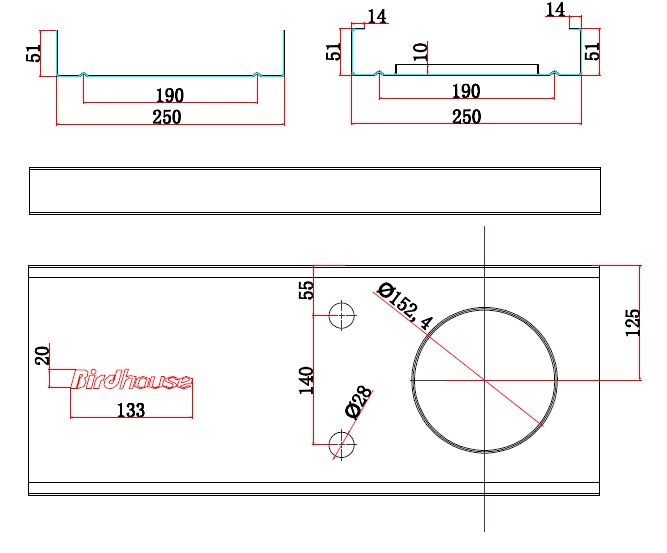

Profile Drawing:

Main Components of SCOTTSDALES Style Joist Framing Machine

1.Manual Decoiler: one set

Un-powered,Manually control steel coil inner bore shrinkage and stop

Max. feeding width: 500mm, coil ID range 470mm±30mm

Capacity: 3-5Ton

With Hydraulic Decoiler for options.

2.Cold Rolling Mill:

Material Thickness:1.0-2.0mm,Material Width:about 369mm for C shape and 349mm for U shape,

With feeding material guide, body frame made from 450# H type steel by welding,Side wall thcikness: 18mm

Rollers manufactured from bearing steel GCr15, precision machined, hard Chrome Coated

Shafts manufactured from 45#,Diameter=φ75mm,precision machined

Motor Driving,Gear chain transmission,14 steps to form

Main Motor=5.5KW , Frequency speed control 380V/50Hz/3Ph

Forming speed approx.12m/min

3.Hydraulic Cutting device

Post cut, stop to cutting, use the same hydraulic motor drive

hydraulic motor:5.5KW, Hydraulic pressure range: 0-16Mpa

Cutting tool material: Cr12, Heat treatment

4.PLC Control System(Touch screen and PLC brand:German Siemens,Inverter brand:Japan Panasonic,Encoder brand:Japan Omron)

Control the quantity and cutting length automatically

Combined with: PLC, Inverter, Touch Screen, Encoder, etc

Cut-to-length tolerance≤±2 mm

Control Voltage 24V

5.Exit Rack Un-powered, two units

6.User's manual in English

Features of Howick,FrameCAD style Floor Joist Forming Machine

This machine can produce SCOTTSDALES style Joists,but with much higher production speed to catch your project time.

After-sale Service

1. The warranty of Howick,FrameCAD style Floor Joist Forming Machine is 2 years after the client receives the machine. Within the one year, we will courier the replacement parts to the client free of charge.

2. We offer technical support for the entire life of our machines.

3. We can send our technicians to install and train the workers in the clients' factories.

Terms of Trade

1. Minimum order quantity (MOQ): 1 piece

2. Delivery time: about 45days

3. Port of loading: port of Xiamen

4. Type of payment: T/T or L/C

5. Export: Australia, UK, Ireland,Greece, Mexico, Brazil ,Israel ,Dubai, Russia ,India, Taiwan, Singapore, Malaysia ,Thailand, Philippines, Myanmar ,Vietnam, South Africa, Mozambique, Zambia, Zimbabwe, Nigeria, Egypt, Sudan, etc.